Our Product

Cantilever Racking

Cantilever racking is specially designed to store long items or items of varying length, such as metal beams, pipes, molding, wooden crates etc.

Depending on the height and weight of the merchandise, either light or heavy-duty racking are available.

Benefits

- Suitable to store long items

- Handling through special MHEs or Forklifts with special attachment

Chute Conveyors

- Gravity Chute

- Spiral Chute

Gravity Chute

Our gravity chutes are unpowered conveyors that uses the force of gravity to move materials over a downward path. The weight of the material would allow them to slide downwards. They are ideal material movement solution in multitier structures with one level.

Benefits

- Easy to install

- Minimal maintenance

- Reliable System

Spiral Chute

Our spiral conveyors are ideal for load transfer from level to level quickly and efficiently without interrupting the conveyor process. The spiral design would guide the speed of the material, thereby allowing it to pass every level at a constant speed. There are ideal to used in multitier structures with more than one level.

Benefits

- Ease of configuration

- Gentle material flow

- Access available on all levels

- Capability to handle different materials

Double Deep Pallet Racking

Double Deep Pallet Racking is also simple & economical racking system which allows 50% selectivity. This racking is also suitable for medium or less variety of SKU's irrespective of quantity. Benefits

- Scalable - Vertically and Horizontally

- Adaptable to varying pallet / load heights

- Need special Material Handling Equipment's with extended reach telescopic / pantograph

- Wide range of beam & uprights offer the most optimal solution for any pallet size/load

- Suitable where SKU variety is not high and ideally 2 pallets of same SKUs are to be kept one behind the other

Drive-In Pallet Racking

A dense storage system conceptualized for managing few varieties of SKUs produced or dispatched in batches. As evident from the name, Material Handling Equipment like reach trucks drive inside the racks to access the pallets. Each storage bay is one pallet wide.

Hightlights

- Can be configured for LIFO/FIFO dispatch

- Suitable for industries involved in batch production

- Safety & Stability elements to support your operation

- Adaptable to varying pallet / load heights

- Wide range of accessories to enhance safety during operations

Flat Belt

Our belt conveyor system is a versatile system for simple movement of materials over long distance. They are capable of handling wide range of bulk materials from fine to large sizes and offer constant material movement.

Advantages

- Capability to adapt to elevations

- Handle wide variety of materials

- Adjustable speed

- Material can be loaded at any instance

Mobile Pallet Racking

Racks on wheels, designed for 100% accessibility to each pallet, while ensuring high density of storage. Remote controlled operations, to create aisles instantly at your command. Best of all worlds, at your fingertips!

Features

- Suits well for any industry with variety of SKUs

- Electrically driven and PLC controlled

- Compatible with all material handling equipment's

- Six levels of safety measures

- Anti-blackout feature to manage power failure

- Automatic lighting system to save power

- Upgradeable from current static racks

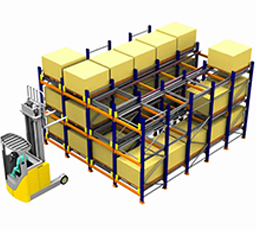

Push Back Racking

Push Back Pallet Racking is another form of dense storage system to utilize maximum ‘Storage Cube’. The sequence of pallet loading is done by pushing the first pallet back. Hence, except for first pallet, the loading of pallet is through “MHE Push”. However, the sequence of pallet availability for unloading is by gravity. For this purpose, the pallet carts are fitted with rollers. This racking has loading and unloading on the same end. Hence by default, this system operates on LIFO (Last In First Out). This system is designed to store pallets of multiple high and multiple deep. Each level shall be dedicated to one type of SKU only.

Benefits

- Suitable where quantity is less while SKU variety is not so

- Suitable to act as buffer storage area

- Adaptable to varying pallet / load heights

- Range of uprights and cart / roller designs to offer the best solution for any pallet size/load

- Compatible to most of the Forklift, Stacker & Reach Truck models

- Variety of Accessories are available to enhance safe pallet movement

Roller

Our roller conveyors are optimized for material movement within warehouses or work centers. Our modular design involves free wheel or electrically controlled roller conveyors which gives flexibility to adapt to any layout. Our solutions are tailor made to every requirement based on specific needs.

Advantages

- Highly customisable

- Flexible design

- Low maintenance

- Speed control mechanism

Selective pallet Racking

Selective Pallet Racking is the simplest & economical racking system which allows 100% accessibility to each pallet. This racking is suitable for large variety of SKU's irrespective of quantity.

Benefits

- Scalable - Vertically and Horizontally

- Adaptable to varying pallet / load heights

- Wide range of beam & uprights offer the most optimal solution for any pallet size/load

- Suitable to all applications such as RM stores, FG stores, Distribution Centre etc

- Compatible to most of the Material Handling Equipment's (MHE) like Forklift, Stacker, Reach Truck

- Variety of Racking Accessories are available to enhance safety during the pallet handling operation of MHEs

- Suitable to offer fast throughput

Accessories

- Pallet Supports

- Entry Guide Pallet Support

- Fork Entry Bars

- Pallet Stopper

- Upright and Row Guards

Shuttle Pallet Racking

Shuttle on racks, designed to swiftly carry pallets to the forklifts. Remote controlled operations to move shuttles within the racks. Configurable in LIFO/FIFO, this solution ensuresfast throughput while improving storage density.

Highlights

- Suits industries with limited variety of SKUs

- Ideal for buffer storage to manage seasonal demands

- Interactive radio transmitter to move goods

- Operation by remote control

- Driven by rechargeable battery

- Compatible with all material handling equipment's

- Highly safe, as forklifts stay away from the racks

- Operate in subzero temperatures up to -30 degrees

- Custom setup to enhance efficiency and speed

- Upgradeable from current static racks

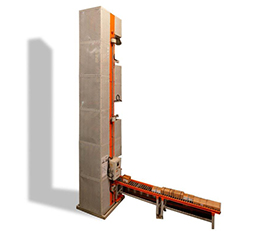

Vertiflow

Vertiflow is a Bidirectional Vertical Conveyor for Moving Discrete goods continuously between various levels both in upward and downward directions. It improves throughput in discrete picking & order fulfilment processes by reducing waiting and travel time. It can be offered as a stand alone product or together with our mezzanine/ multitier shelving solutions.

Features

- Self-supported structure

- Variable speed

- Three side access

- Portable System

- Fire Resistant System

Very Narrow Ailse Racking

VNA stands for “Very Narrow Aisle”. There are Material Handling Equipment's which needs very narrow aisle, i.e. less than 2 meters. Hence more pallet positions are possible compared to other MHEs. VNAs can reach up to 12 meters high.VNA Racking is nothing but Selective Pallet Racking but compatible to VNA Equipment. This VNA equipment needs special guides. These guides may be mechanical rails or electrical wires. Mechanical guide rails are widely practiced for ease and economy. However, VNA equipment's demand high level of floor accuracy.

Benefits

- Scalable - Vertically and Horizontally

- Adaptable to varying pallet / load heights

- Need special Material Handling Equipment's and guides

- Wide range of beam & uprights offer the most optimal solution for any pallet size/load

- Suitable to all applications such as RM stores, FG stores, Distribution Centre etc.

- Offer fast throughput